In addition to a comprehensive range of familiar finishes and textures, 55HX®is suited to sublimation printing, a process where full colour graphics or photographs can be transferred direct to the material providing almost limitless creativity to designers and specifiers.

Stock Range

| Size (mm) | Mill Finish with PCI | Anodised Natural (10 micron) | Anodised Natural (15 micron) |

|---|---|---|---|

2000 x 1000 x 1.0 | |||

2000 x 1000 x 1.5 | |||

2000 x 1000 x 2.0 | |||

2000 x 1000 x 2.5 | |||

2000 x 1000 x 3.0 | |||

2000 x 1000 x 4.0 | |||

2000 x 1000 x 5.0 | |||

2500 x 1250 x 1.0 | |||

2500 x 1250 x 2.0 | |||

2500 x 1250 x 3.0 | |||

3000 x 1250 x 2.0 | |||

3000 x 1250 x 3.0 | |||

3000 x 1500 x 1.0 | |||

3000 x 1500 x 1.5 | |||

3000 x 1500 x 2.0 | |||

3000 x 1500 x 3.0 | |||

3500 x 1500 x 3.0 | |||

4000 x 1500 x 2.0 | |||

4000 x 1500 x 3.0 | |||

Coil | |||

1000 x 1.5mm | |||

1250 x 1.5mm | |||

1000 x 2.0mm | |||

1250 x 2.0mm | |||

1500 x 2.0mm | |||

1250 x 2.5mm | |||

1000 x 3.0mm | |||

1250 x 3.0mm | |||

1500 x 3.0mm |

Chemical Composition Limits

| Alloy | EN Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other Each | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|

55HX® | 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.5-1.1 | 0.1 | 0.25 | - | 0.05 | 0.15 |

(All data on wt. -%)

Typical Mechanical Properties

| Alloy | Temper | Thickness (mm) | Tensile Strength Rm (MPa) | Yield Strength Rp0.2 (MPa) | Elongation A50 (%) |

|---|---|---|---|---|---|

55HX® | H14 | 0.2 ≤ 1.5 | 145 - 185 | min 120 | min 2 |

55HX® | H14 | 1.5 ≤ 3 | 145- 185 | min 120 | min 3 |

55HX® | H14 | 3 ≤ 5 | 145 -185 | min 120 | min 4 |

Key Benefits

- Color uniformity across various batches

- Corrosion, UV- and scratch resistant after anodizing

- Excellent deformation properties

- Very good bending properties

- Outstanding durability

- Easy cleaning

- 100% recyclable

- Non-combustible (European Fire Class A1, NFPA 285)

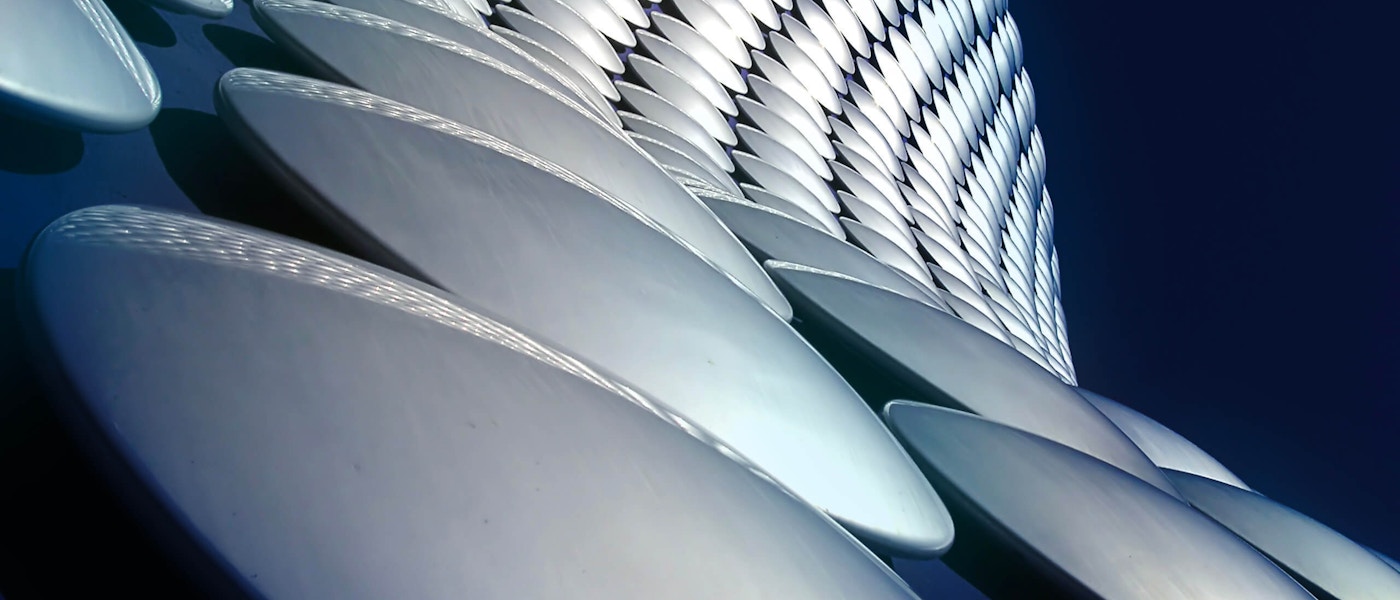

Applications

- Façades and wall cladding

- Ceilings, roofs and balconies

- Pillars and escalator casing

Processing

Handling

Loading and unloading of 55HX® should be done very carefully to avoid scratches and other surface defects.

Storage

55HX® should be ordered with paper or protective film on the visible side. The UV resistant film can be removed without residue, provided it was protected against water during storage at temperatures between 5°C and 30°C.

Fabrication

Processes such as laser cutting, punching, perforating and folding, should take place prior to anodizing. All processes influencing the surface quality must be avoided on the visible side. Therefore welding and soldering should only be done at the non visible side.

Installation

During wall cladding, all panels need to be put up in the same rolling direction. Thicknesses sizes < 2mm and ≥ 2mm should not be intermixed.

Cleaning

Once a year wash with water added with a neutral soft detergent. Afterwards, rinse with plain water and dry with a soft and absorbing cloth.