Introduction to Nylons 6 and 66

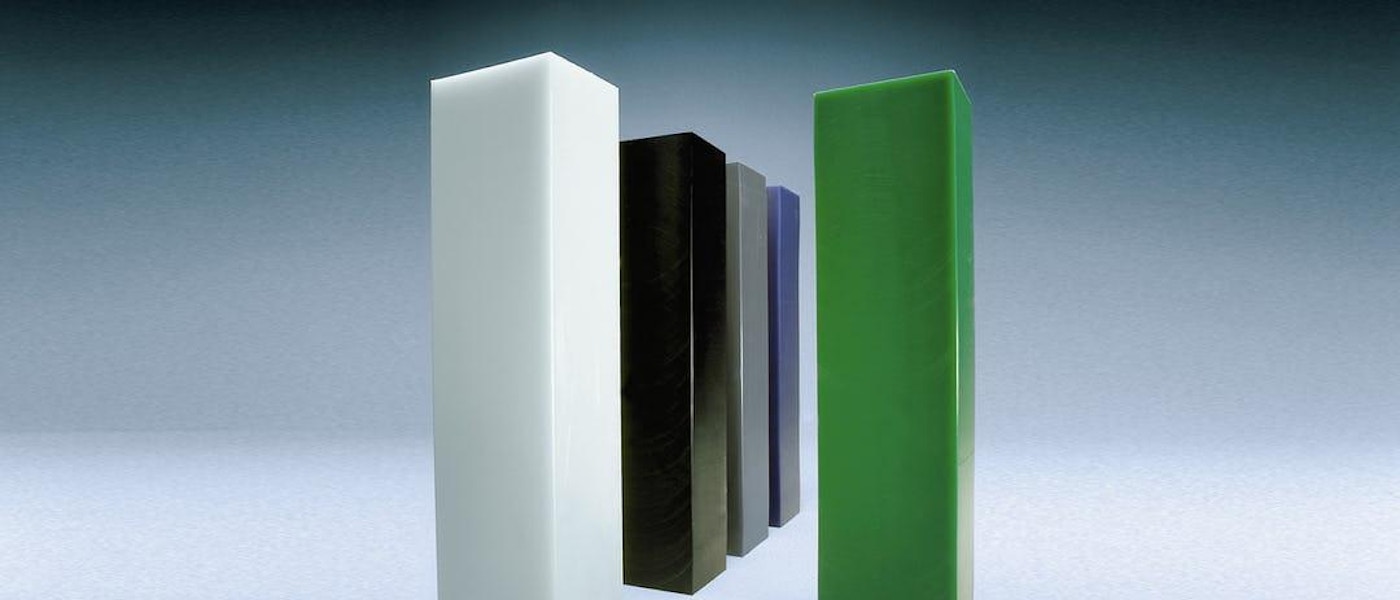

Nylon 6 and Nylon 66 are both commonly used synthetic polymers known as polyamides.

The numbers represent the amount and variant of the carbon atoms in the chemical structure from which they are formed.

For example:

Nylon 6 is created from caprolactam, which consists of 6 carbon atoms, while nylon 66 is produced from adipic acid, which has 6, and hexamethylene diamine, which also has 6.

Most nylons, including 6 and 66 are semi-crystalline and possess good strength and durability and are ideal for demanding projects.

History of Nylon 6 and 66

Nylon 66 was discovered at the Du Pont Company in the 1930s, giving the world the first synthetic fibre.

This was quickly introduced into the commercial arena and became the backbone of the new synthetic fibre industry.

Following this in 1939, nylon 6 as it was to be known, was created in Germany by Paul Schlack.

Both fibres have become highly important in today’s fibre trade, and their uses and applications continue to be discovered and improved.

Technical comparisons of Nylon 6 and 66

- The number of units within the polymer chains of nylon 6 and 66 is 130 and 65 respectively.

- Both iterations comprise weak basic amino acids and acidic carboxylic acid end groups.

- They are both strong fibres of moderate elasticity, even after being drawn.

- Both nylons have high tenacity variants that are applied to industrial applications, and both have multiple strands of property definitions based on changes in polymerisation and drawing conditions.

- Nylon 6 has a lower elastic modulus and better elastic recovery and therefore provides softer, more flexible fabrics.

- At higher temperatures, like 180°c, nylon 6/6 shows markedly better heat age strength at 11.5kg, compared to nylon 6 of only 2.5kg.

- The fibres of nylon 66 are 33% more resistant to abrasion than nylon 6, withstanding up to 60,000 cycles compared to 40,000 in the case of nylon 6.

- With low creep, and more crystallinity, nylon 66 is slightly more rigid, allowing good stretch recovery and higher abrasion resistance.

Properties of Nylon 6 vs Nylon 66

The properties and variations within commodity plastics, and in this case nylons, are not as stark as they would be with, say, steels.

Having said that, when we begin to subtly alter the underlying structure and its fillers and additives, many more commodity and specialist grades are achievable creating a wider range of properties and as a result, a broader scope of application.

As polyamides, while having their own defined benefits, they do also share many core performance characteristics.

- Superb wear resistance

- Rigidity, hardness and toughness

- High mechanical damping

- Good sliding properties

- High mechanical strength

- Good for Electrical insulation

- Strong resistance to high energy radiation

- Good machinability

So, while maintaining these core property values, they do still provide different attributes.

Nylon 6 vs Nylon 66: Differences and Comparisons

Nylon 6 | Nylon 66 | |

Resistance to Hydrocarbons |

| |

Mould Shrinkage* |

| Higher Shrinkage |

Impact Resistance |

| |

Easiness To Colour |

| Less |

Water Absorption Speed |

| |

Recyclability Potential |

| |

Molecular Mobility |

| |

Elastic Recovery |

| |

Dye Affinity |

| |

Crystalline |

| Less |

Heat Deflection Temperature |

| |

Melting Point | (215° - 220°c) | (250° - 265°c) |

Chemical Acid Resistance |

| |

Rigidity |

| |

Colour-Fastness |

| |

Temperature Resistance |

| |

Ability to clean |

| |

Elastic Modulus |

| |

Internal Structure | Less compact |

|

Polymerization Formation | Open Ring |

|

Moisture Regain | 4 - 4.5% | 4 - 4.5% |

Monomer Requirements | 2 |

|

Density | 1.2 g/ml |

|

Degree of Polymerization | 200 |

|

Mould Shrinkage

Most notable of these distinctions is mould shrinkage.

Nylon 6's lower mould shrinkage gives more assurity of accurate dimensions for all manufactured goods.

Whereas the greater mould shrinkage of Nylon 66 means that when it is exposed to cooler air in solidification, its material shape will have more susceptibility to alteration after processing, which must be factored in.

Other highly relevant differences are their relative water absorption rate and heat deflection values.

Nylon 6 has higher water absorption and lower heat deflection temperature, and as such is less suited to applications where high-temperature water is present.

Nylons Use As An Engineering Plastic

Nylons take their place among the engineering plastics due to a valuable combination of strength, rigidity and toughness.

Applications vary from gears, door handles, bearings, brushes, sprockets, power tool housing and even bicycle wheels, to name just a few.

When considering using nylon for a project, a vital factor is that nylons do absorb moisture, which can alter its properties and thus, its dimensional stability.

To offset this, a form of reinforcement, often glass, can be introduced to create an incredibly strong and impact resistant material.

Performance Comparison of Nylon 6 and 66

Nylon 6 Performance

Nylon 6 excels in damper conditions, having better impact strength and flex fatigue than nylon 66.

It can also be processed at a lower temperature and is less crystalline in structure, meaning mould shrinkage is reduced.

It is also available in transparent grades.

However, Nylon 6 does have the highest level of absorption of any nylon, showing dimensional instability and fluctuating mechanical and electrical performance, some of which can be countered by alloying with low-density polyethylene.

As a result of all of this, Nylon 6 tends to be used for components requiring higher impact strength than nylon 66, but where higher yield strength is not a prerequisite.

Nylon 6 can be used in a host of varying applications, including:

- Stadium seats

- Hosiery

- Radiator grills

- Industrial yarn

- Toothbrush fibres

- Wear Strip and Chain Guards

- Machine Guards

- Rotor slot wedges

- Firearms

- Upholstery

- Heavy-duty fabrics

- Circuit insulation boards

- Switchgear

- Seals

Nylon 66 Performance

Nylon 66 is the most commonly used of all the nylon groups:

Without fillers, it retains strength across the widest range of temperatures and the highest level of moisture exposure than any other nylon.

It also exhibits good abrasion resistance and the lowest permeability to mineral oils, gas and fluorocarbon refrigerants.

Nylon 66 is also reported to have better chemical resistance to saturated calcium chloride, and many reports suggest that 6/6 has better weathering properties too.

Nylon 66 is also a popular material for electrical components, and as a replacement for metals in die-cast hand tool bodies.

Another significant advantage is its Heat Deflection Temperature (HDT) compared to Nylon 6. Therefore, Nylon 66 is clearly a great choice in wet conditions, but not so much when dry.

Nylon 66 has high moisture absorption, low impact strength, and poor ductility. It is also the most susceptible to UV penetration and oxidative degradation.

Nylon 66 is often found in:

- Friction bearings

- Tire cord

- Carpets

- Battery modules

- Automotive airbags

- Conveyor belts

- Parachutes

- Apparel

- Seat belts

It is important to note that both of these nylon groups have a lower resistance to weak acids than 6/10, 6/11 and 6/12. And, that ALL nylons will substantially degrade when exposed to fermented 15% ethanol gas.

Final Thoughts and Comparisons

Processing method, aesthetics, and mechanical characteristics must all be taken into account when assessing the right nylon for a project.

Nylon 6 for example, is a great choice if a lightweight Engineering Plastic is a prerequisite. It has good insulation properties, and damping values, as well as good toughness, rigidity and hardness.

Nylon 6 is also the standout choice if resistance to high impact and internal stresses are required and if aesthetics are a factor. Its lustrous look and ease of colouring make it the more attractive option on the eye.

Nylon 6 is also an ideal choice for applications in the automotive industry, as well as military and industrial components, commonly used for firearms, engines, gears and so on.

It is important to note, however, that Nylon 6 is not the right option where the high water temperature is a factor due to its high water absorption and lower heat deflection rate.

Here, Nylon 66 would be a better choice.

In contrast, Nylon 66 should be utilized where a high performing engineering plastic is needed in higher temperature environments.

Its greater rigidity and good tensile modulus make it a fantastic material for applications that need to last longer over repeated performance, such as friction bearings, tire ropes or radiator caps.

There are also many more nylons to consider that each has different performance advantages and property values, so it can be seen that within the plethora of nylons, selecting the right one is often a case of making a favourable compromise.

For this reason, we advise seeking expert advice before putting pen to paper on any nylon-based project.

Looking for more information on Nylon 6 vs 66? Contact your local centre and we'd be pleased to help you further!