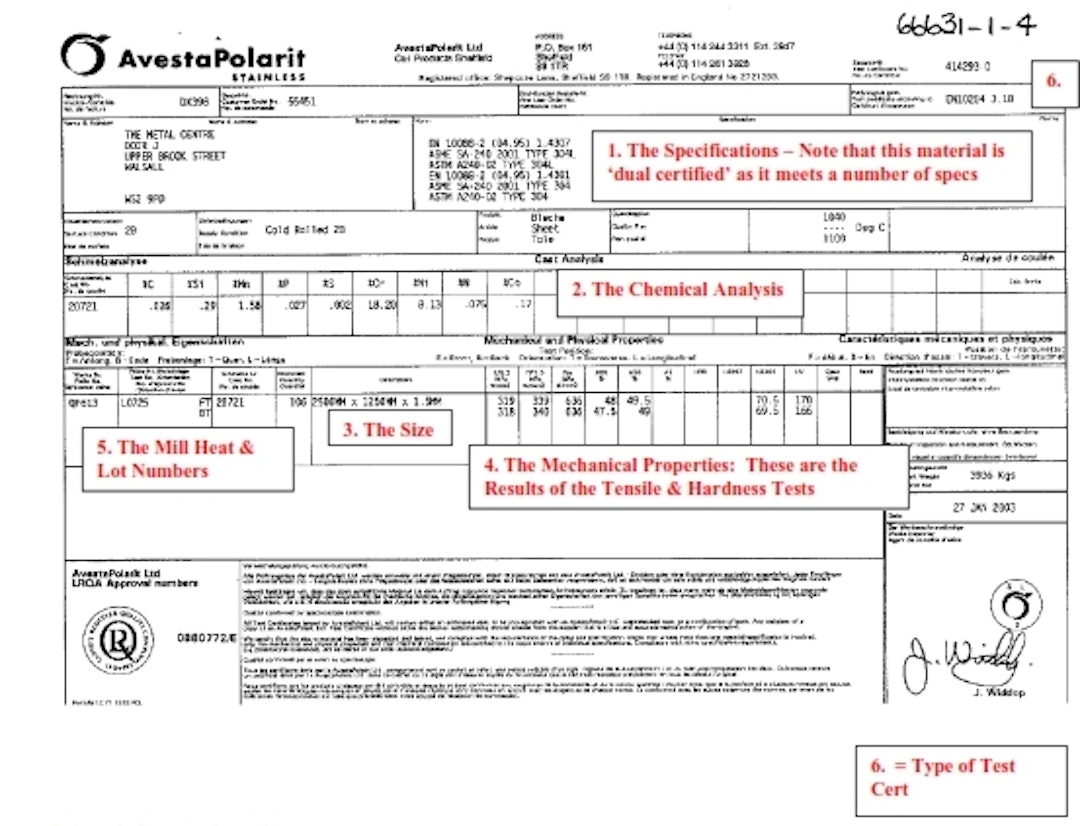

What is a test Certificate and why is it important?

- It is effectively a guarantee that ensures traceability and protects all parties.

- In many cases the material has no value to a customer unless it is accompanied by a test certificate

This is when a certificate shows that material meets, and can thus be sold as, more than one specification, such as types 304 and 304L .

This is sometimes supplied instead of a test certificate with material that is for less critical applications – It can be issued by anybody and may have limited value - If a customer requires true Test Certificates then a Certificate of Conformance will not be acceptable:

Just above Caption 5 in red above there is a box containing the letters ‘FT’ and ‘BT’ – These indicate the source and orientation of the tensile test sample where:

These are tests carried that do not damage the product being tested, which is then delivered to the customer after testing. They are carried out as part of a quality control process to ensure that the product meets the standard/s to which it is being supplied. They are often carried out in-line during production. Examples include Radiographic (X-Ray), Hydrostatic, Ultrasonic, Eddy-Current and Dye-Penetrant Testing.

This is usually used to determine whether a weld is sound. It involves subjecting a weld or weld area to an X-ray source with an X-ray sensitive film plate on the under side of the weld. The results are shown on the developed film (a photomicrograph) and interpreted according to specification.

This involves inducing eddy currents into the material by exciting a coil which surmounts two narrow search coils surrounding the material. Any discontinuities in material are found by comparing the electrical conditions that exist in the two search coils. The fault signals are amplified and can be shown on a cathode ray tube or as an audible signal.

This test involves ultrasonic sound waves being aimed, via a coupling medium, at the material to be tested. A proportion are bounced back at the interface but the remainder enter the material and bounce from the internal surface, to the external surface, where a transducer converts them into electrical energy. This is then monitored on a cathode ray tube where results are compared with those from a calibration standard. Any deviations from the standard are visible, thus indicating cracks or internal defects.

This is used to detect cracks and involves spraying a dye on the area to be tested. After allowing time for penetration the surplus dye is removed and the area is then sprayed with a white developer. Any faults are revealed as coloured lines or spots caused by the developer absorbing the dye seeping from the cracks. If more sensitive results are required, a fluorescent dye is used and the same process is followed. When viewed under ultraviolet light any defects show as a highly fluorescent line or spot.

This is used to test manufactured items under a pressure equivalent to or greater than pressure to be encountered in service. It involves filling the tubes or fittings with water, which cannot be compressed, and increasing the pressure inside the tube to that specified.

Instruments are available to measure the reflectivity of a surface which is given as a percentage between 0 and 100.

Instruments are used to measure the surface roughness as a Centre Line Average (CLA) in Microns (µ).

This method of testing is used when trying to detect discontinuities in material of ferromagnetic structure. The method is based on the principle that an imperfection will cause a distortion in the magnetic field pattern of a magnetised component. The imperfection can be revealed by applying magnetic particles to the component during or after magnetisation

These non-destructive tests determine the resistance of a material to indentation and are considered an indicator of tensile strength.

A standard size hardened steel ball is indented into the surface of material by an applied standard load for a duration of 15 seconds. Typically a 10 mm ball with 3000, 1500 or 500 kgf load, or a 5 mm ball with 750 kgf load is used. The diameter of the impression is measured accurately by microscope and converted to a hardness value using tables. (Brinell testing is not suitable for tubular products less than 51 mm in outside diameter, or less than 5.1 mm wall thickness.)

This determines hardness by measuring the depth to which a diamond cone or hardened steel ball, under specific load, penetrates the material.

Two loads are used, a minor load (10 kgf) and then a major load (100 or 150 kgf), the difference in indentation being used by the Rockwell Hardness machine to determine the Rockwell number.

The number increases with increasing hardness and is displayed or printed by the machine.

Two scales are most frequently used:

A Rockwell superficial hardness machine is used for testing very thin wall thickness tubes:

The minor load used is 3 kgf.

(Also called Vickers Pyramidal Harness Number – VPN)

This determines hardness by measuring the impression left in material by a diamond pyramid under a standard load for a specified time. The square impression is accurately measured, and its area calculated. The Vickers Hardness Number is calculated by dividing the load (kg) by the area of impression (mm2).

Most British and European specifications no longer require specific hardness values (maximum, minimum or range.

However, most test certificates do carry a hardness figure as all American specifications require a hardness value.

Although it can be related to strength, hardness can of course only be measured at the surface and is thus a relatively poor indicator of the material’s strength.

Thus most engineers consider the hardness to be of little interest or use.

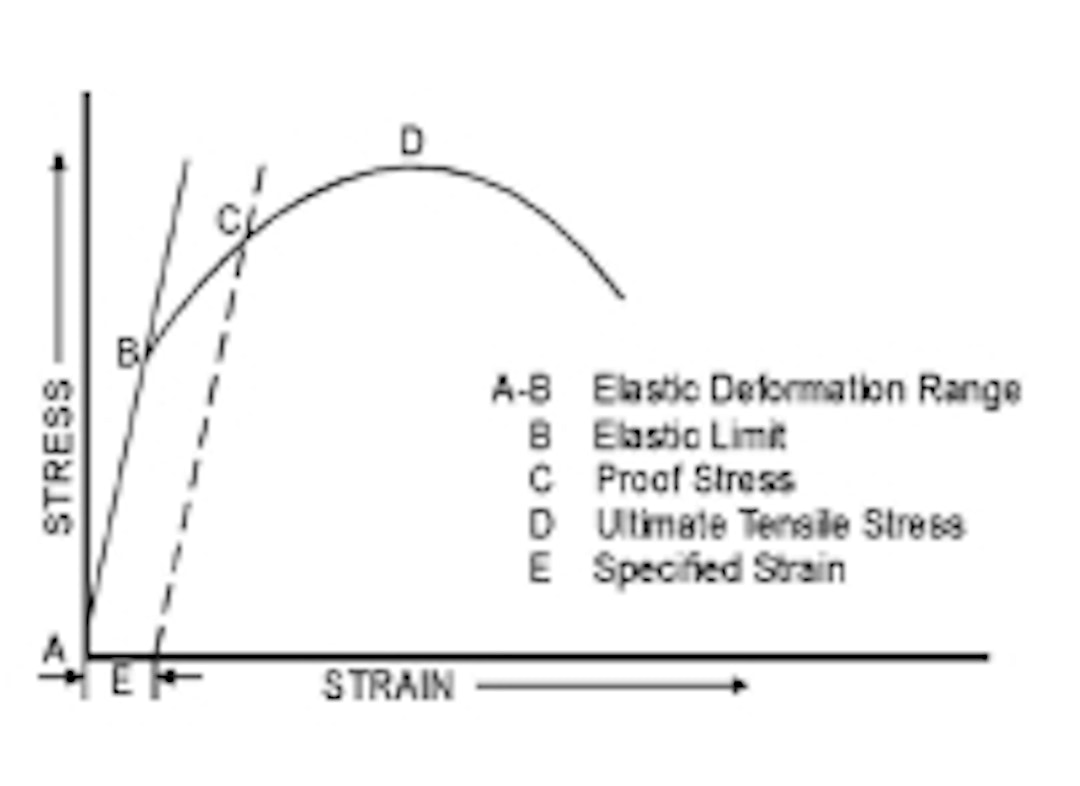

This is probably the most revealing of the mechanical tests that can be performed upon a specimen of pipe or tubular product material. A longitudinal specimen1 of known cross sectional area is taken from the material and gripped at each end, and then pulled apart until fracture occurs. By recording the gradually increasing load applied and the extension during loading a Stress-Strain Graph can be plotted (see diagram).

1The longitudinal specimen may be a full size tubular section with metal plugs fitted in the ends to allow gripping by the test machine, or for larger tube sizes a strip may be cut from the tube. Transverse tension tests may also be performed using a ring expansion method or for larger tube sizes (e.g. greater than 8”) a transverse strip may be used.

(D in diagram) – This is defined as the ‘maximum tensile stress that the material is capable of sustaining’ or the load required to break the material.

(C in diagram) – The load at which the sample is permanently elongated by a specific percentage of the original length. This percentage elongation (corresponding to the distance E on the graph) is commonly set at 0.2% or 1.0%. The dotted line to C on the graph is drawn parallel to the line A-B.

This is a measure of ductility based on the extension of the test piece at the point of fracture, expressed as a percentage. The fractured test piece is carefully fitted together and the distance between gauge marks on the test piece is measured and compared with the original distance between them (normally 50mm). On modern equipment this measurement is normally automated.

(B in diagram) – The stress at which the test piece is permanently deformed. The graph deviates from the straight line at point B. This exact point is very difficult to measure and hence the Proof Strength is normally used. Initially the graph is a straight line, and in this region the material is still elastic so can be expected to return to its original dimensions if the

load is removed.

In the tensile test, the is ratio between Stress and Strain within the elastic deformation range (A-B) is known as Young's Modulus of Elasticity.

This is the reduction in cross- sectional area of the test piece after tensile fracture expressed as a percentage of the original cross- sectional area.

Notes

These are tests carried out on samples of a product, where a representative sample is destroyed by the testing process. Corrosion Testing (see below) also falls into this category.

In this type of test, a sample is subjected to sudden force to measure its toughness or resistance to shock. The two main methods are Charpy and Izod.

In this test a specimen is supported at both ends and subjected to a blow by a Pendulum

immediately behind a prepared notch, either 'U' or 'V' shape in cross section. The energy absorbed in fracturing the specimen is measured by the height to which the pendulum rises after breaking the test piece. These tests can be carried out at various temperatures to determine the performance of material at either elevated or cryogenic temperatures. At higher temperature specimens fracture by a ductile mechanism, absorbing much energy. At low temperatures they fracture it a brittle manner absorbing less energy. Within the transition range a mixture of ductile and brittle fracture is observed. Minimum test results for absorbed energy, fracture appearance, lateral expansion or a combination of these, may be specified.

These tests prove the ductility of certain tubular products and confirm the soundness of welds.

A bend test involves bending a sufficient length of full size pipe through 90° or 180° degrees around a mandrel having 12 or 8 times the nominal pipe diameter. This checks the ductility and weld soundness of pipe (2 in and under) used for coiling. Transverse guided bend tests may also be specified to check the ductility of fusion welds. These involve bending the root or face of the weld in a specimen against a plunger.

This is usually applied to tube and involves flattening a sample of tube between two parallel faces without the tube showing flaws or cracks. The length of the test piece and degree to which it is to be flattened (i.e. the distance between the parallel faces) are specified.

This tests the ability of boiler tubes to withstand bending into a tube sheet. It involves the tube having a flange turned over a right angle to the tube body.

A cone is forced into the end of the tube. The end of the tube is expanded by a specified increase in diameter without splits or cracks. The included angle of drift is also specified.

NOTE:

When testing welded tube the purpose of a test such as the Flare Test is often to confirm that the weld and the heat-affected zone (HAZ) around the weld is at least as strong as the parent material. Thus is some test procedures, notably BS 1139 for Extruded Scaffolding Tube the test is failed if the tube splits on the weld or in the HAZ.

Fatigue is a metallurgical phenomenon whereby a material subjected to cyclical stresses over a long period will eventually fail even though the stress is well below the elastics limit / proof stress. An example is bending a paper-clip backwards and forwards. The only way to test a material’s fatigue behaviour is to simulate service conditions, which is length and costly procedure.

Creep is a metallurgical phenomenon whereby a material that is subjected to stress over a long period will gradually elongate even though the stress is well below the elastics limit/proof stress. This occurs more readily and more quickly at elevated temperatures. The only way to test a material’s creep behaviour is to simulate service conditions, which is length and costly procedure.

Various corrosion tests are available using different corrosive environments to indicate the performance of material under heavy duty applications.

This test detects the susceptibility of a material to inter-granular attack and involves the use of boiling nitric acid. The test samples are immersed in the solution at a concentration of 65% by weight for five 48 hour periods. The effect of the acid on the material is measured by the loss in weight after each period and the corrosion rate assessed as a thickness loss in a given time.

This test detects inter-crystalline corrosion and involves the use of boiling copper

sulphate/sulphuric acid solution which must contain solid electrolytic copper. The test samples are immersed in the solution for 15 hours. After

immersion the samples are bent through 90

degrees and are considered resistant to inter- crystalline corrosion if they bend without cracking.

This is a method of determining the corrosion properties of stainless steel by producing polarisation curves which relate electrode potentials and a current flow. The shapes of the curves, which are very sensitive to microstructure and composition, provide a critical method of assessing the corrosion properties of stainless steel.

Weld Decay is a form of intergranular corrosion occurring in the heat-affected zone of the parent metal parallel to the weld. Test samples are first sensitised and then immersed in the solution for 72 hours. After the immersion the samples are bent through 90 degrees and are considered satisfactory if no cracks are present. Susceptibility to this attack is assessed using one of these standard tests:

i. Test as given in BS1449/BS1501 using boiling copper sulphate/sulphuric acid.

ii. Test as given in ASTM A262 Practice C using boiling nitric acid.

Low carbon grades perform better in the more severe (latter) test.

Experienced multi-product specialists

In-house state of the art processing facilities

Large fleet of bespoke delivery vehicles

Opening Times