We supply an extensive range of material suitable for precision engineering, including

The specialist supplier of high specification metals & plastics for the manufacture of precision engineered components.

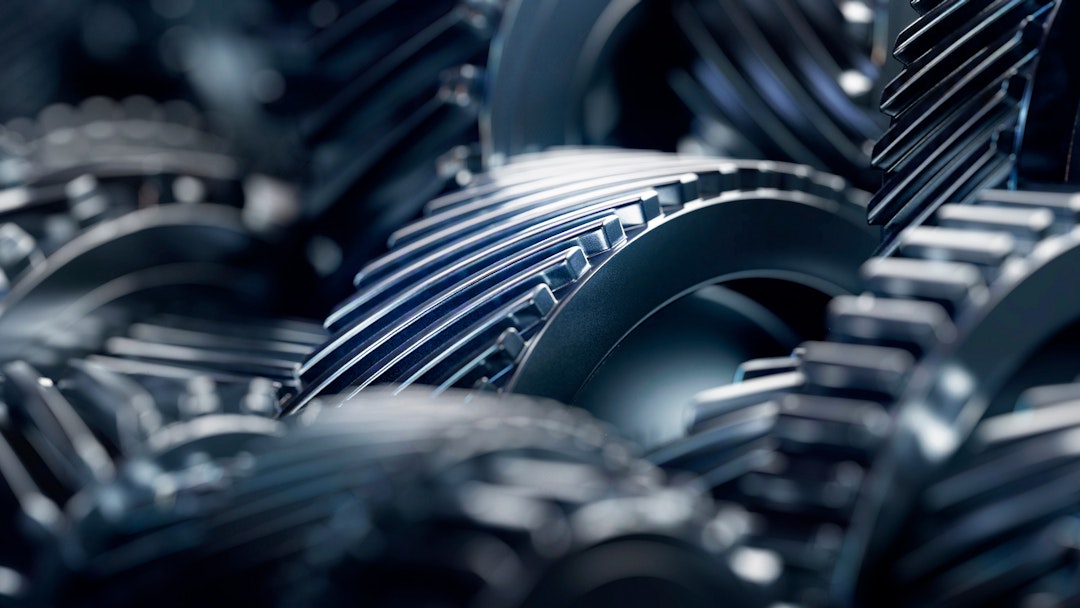

Precision machining creates accurate and specialised parts for a diverse range of applications. Precision machining providers must work with a variety of different materials whilst maintaining the same quality, precision, and accuracy of the part created.

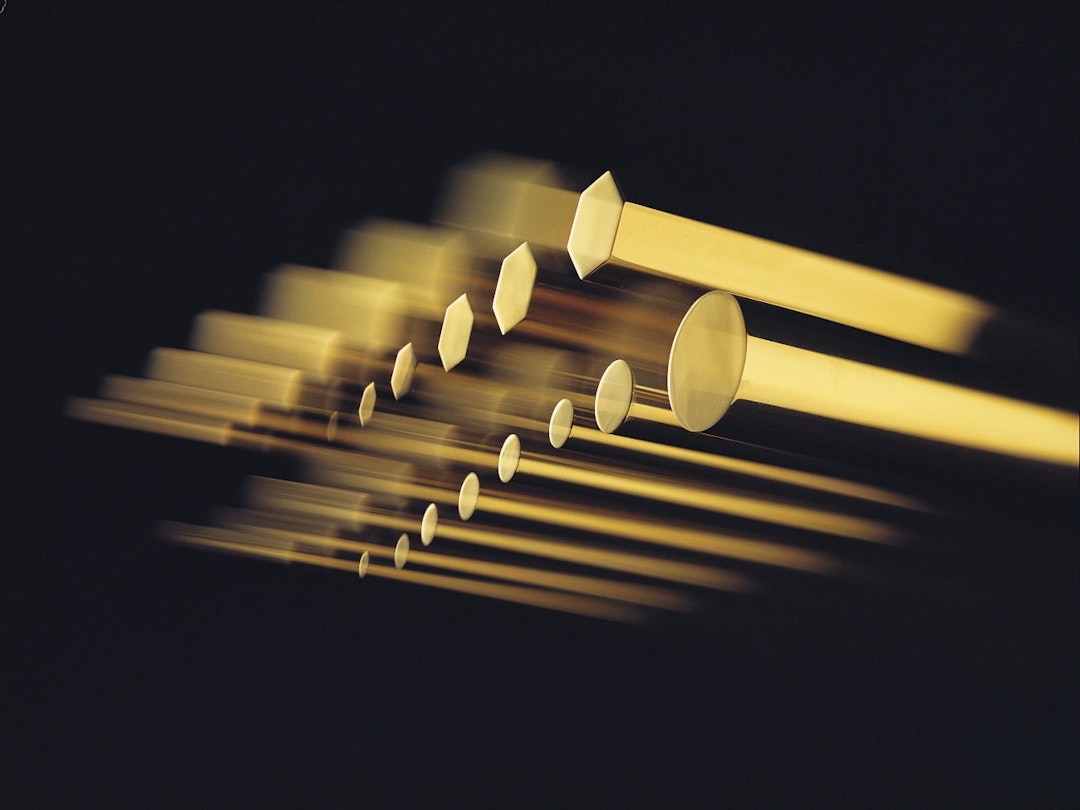

Our extensive product range includes aluminium, stainless steel, brass, copper, bronzes, nickel alloys, titanium and engineering plastics. Material is available in round bar, hexagon, flat bar, tube, pipe, sheet and fittings for use in precision engineering, repetition engineering, tooling shops, auto-turning, bar feeding, and precision & machined components.

We also offer JIT deliveries and a range of processing services including cutting, packing, fabrication and processing.

Grades

Your search did not match any items. Please ensure all words are spelled correctly or try different / more general keywords.

- Aluminium

- Stainless Steel

- Titanium

- Copper

- Brass

- Bronzes

- Nickel Alloys

- Engineering Plastics

Available in round bar, hexagon, flat bar, tube, sheet and pipe & fittings, our extensive range of products are used for precision engineering, repetition engineering, tooling, auto-turning, bar feeding and precision & machined components