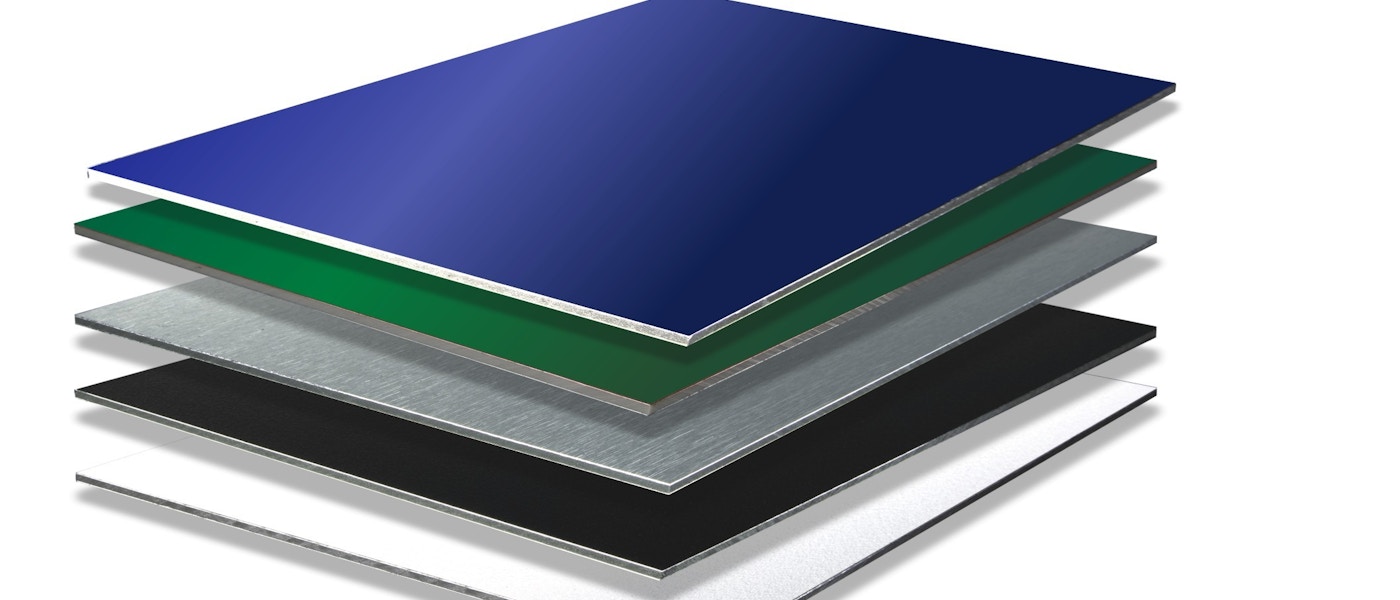

Our range of white ACM is suitable for digital printing. It features a bright white paint finish creating the perfect surface for all colours when digitally printing direct to surface. The results are brighter and more vibrant colours, making your print stand out brilliantly.

The specially developed finish has vastly improved ink adhesion not only producing a long lasting print but also reducing the chance of surface damage. It has also been developed for use with the next generation of LED curing UV printers.

A special low-tack film is used on this material to ensure it leaves no residue. This reduces cleaning time and the risk of any adhesive being left on the material.