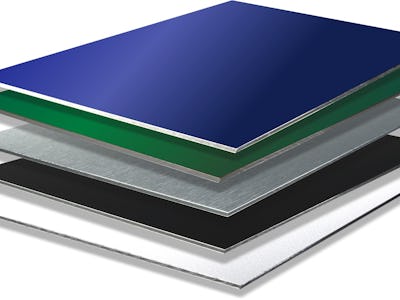

Aluminium Honeycomb Panels

The first choice for quality and service, Righton Blackburns satisfies the diverse and exacting requirements for high strength and corrosion resistant material for all marine markets, including:

Your search did not match any items. Please ensure all words are spelled correctly or try different / more general keywords.